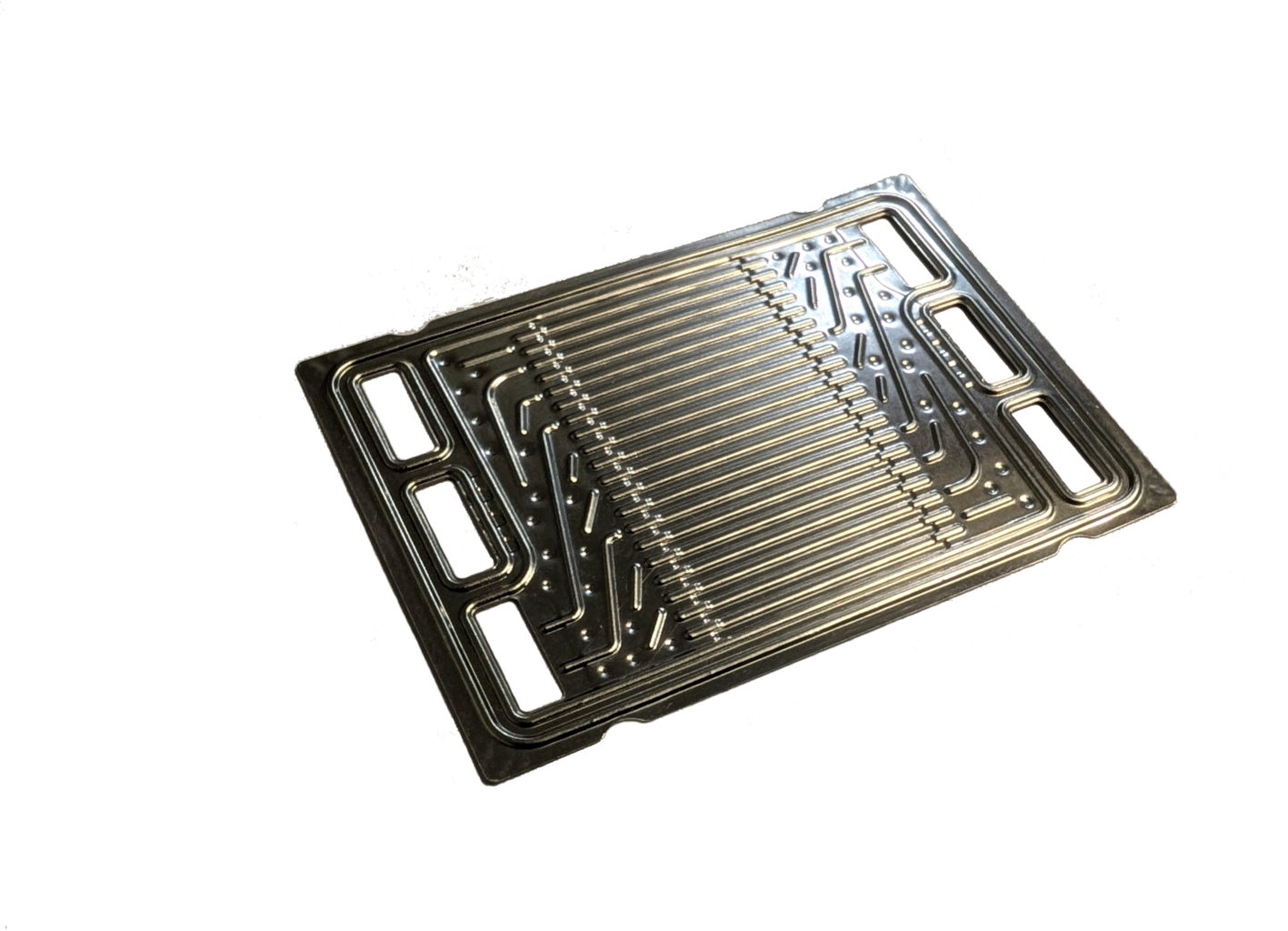

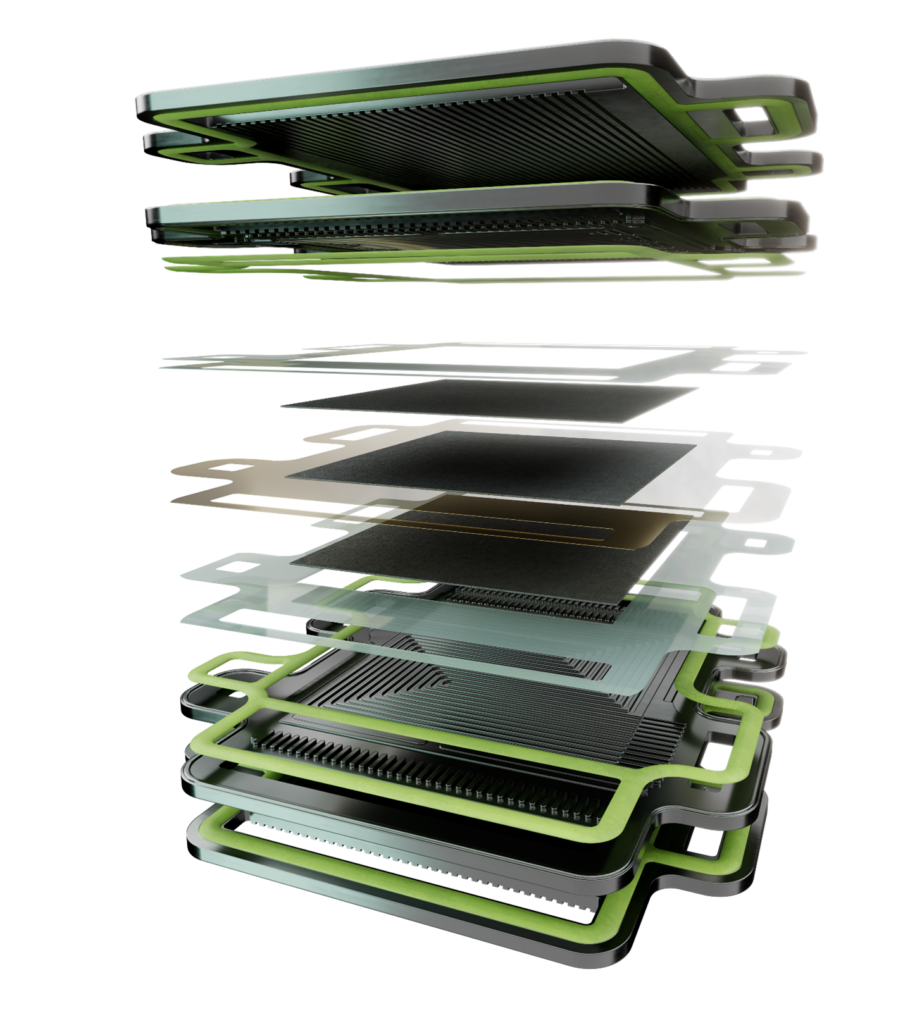

The success of the CO2-neutral hydrogen economy depends largely on the production capacities and costs for fuel cells and electrolyzers. Metallic bipolar plates (BiP) account for 70-80% of the manufacturing costs of a fuel cell stack.

As part of the joint project, a novel, continuous process combination for the forming of metallic bipolar plates is being developed. The goal is to produce up to 120 BiP/min on an industrial scale within the specified tolerances. The new process strategy combines continuous forming by hollow embossing rolling with the use of locally applied heat spots by means of a laser source.

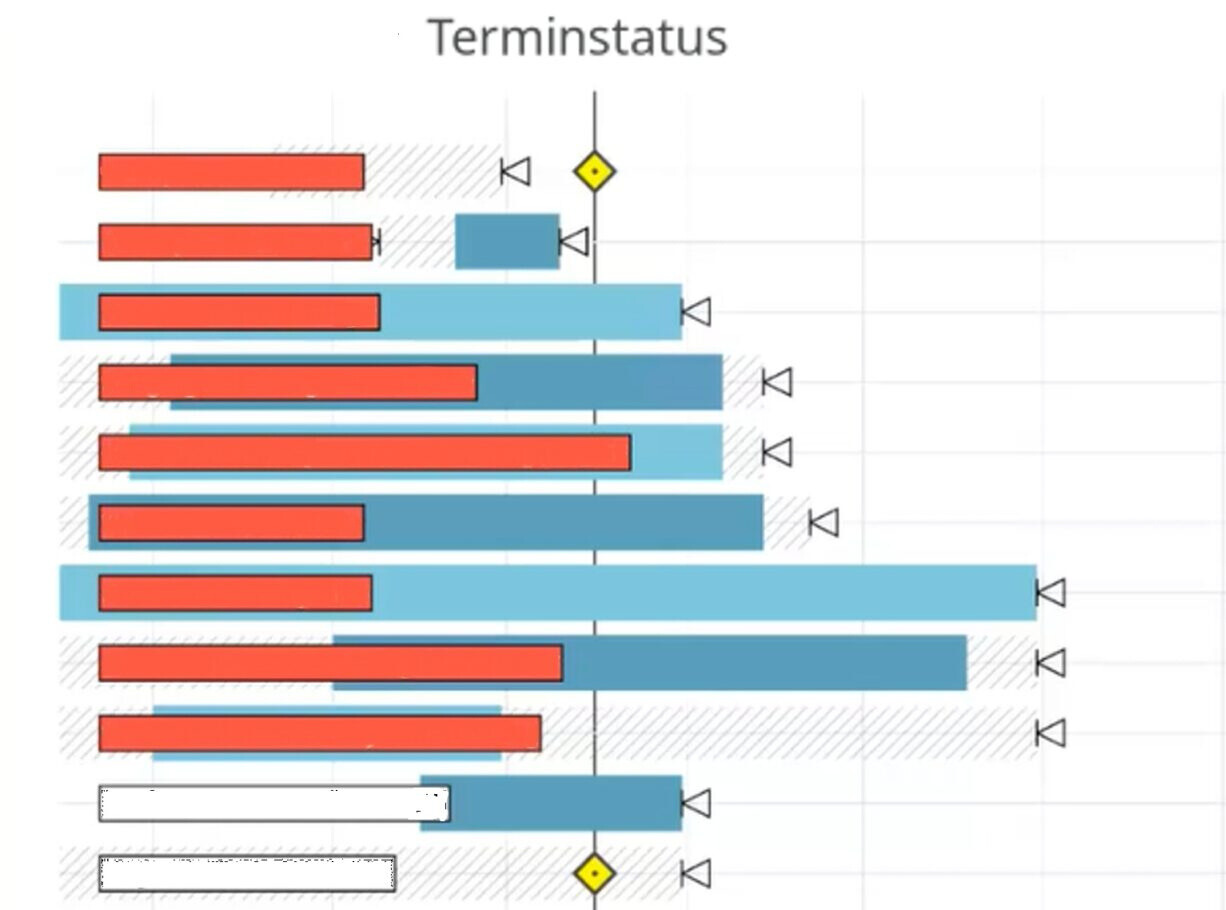

In this project, we are developing a demonstrator production plant (TRL 5) to show that the production, as we imagine it, is actually possible.

We are implementing the project together with our partners Sächsische Walzengravur GmbH, TU Dresden – Professur für Formgebende Fertigungsverfahren and TU Dresden – Professur für Laserbasierte Fertigung.

Project sponsor: SAB

Duration: 10/01/2025 – 12/31/2027